The Ensign:Standard is a robust sewage treatment unit with no internal moving parts, allowing for simple installation, commissioning, and minimal long-term maintenance and cleaning.

Marsh Ensign sewage treatment plants are designed to deliver efficient, reliable, and cost-effective operation.

Units range in size from 4 to 16PE, with larger capacities available up to 50PE. For units above 16PE, please contact our office for pricing. With a wide range of ancillaries, units from this range can meet most site, consent, and budget requirements.

Tested and approved to BSEN12566-3/A1:2009, all Ensign units provide treatment within national consent requirements. Published test results show treated effluent concentrations of 11.5:19.2:8.4 mg/ltr (BOD:suspended solids:ammonia), achieving approximately 97% pollutant removal under test conditions.

Key Features

Inlet & Outlet with ‘Forsheda seal’ - provides flexibility in the joint for easier installation.Optional risers to increase invert depth are available.

Compressor housing – internal or external options available - the compressor can be housed internally or externally with no difference in cost.External recommended to increase compressor life, and supplied as standard on 4PE, shallow and pumped outlet versions.

PVC pressure pipe/diffuser(s) - provides a protective conduit for the air diffuser line. Can be easily removed for maintenance and cleaning.

Bio-media - high specification bio-media (310m3 per m2) and membrane diffusers ensure even circulation to eliminate ‘dead spots’. The bio-media is contained by a stainless steel securing mesh to ensure no migration during handling or potential flooding.

Stainless steel mesh - retains media in aeration chamber during transportation and handling, and in the event of flooding.

32mm sludge return - larger diameter sludge return prevents the possibility of blockages and improves system circulation. Provides higher effluent quality whilst balancing flow over a 24 hour period or periods of intermittent use.

Impermeable lid - heavy duty lid/frame improves strength and durability whilst blending into the surrounding environment. (Regular lid on Ensign:Standard models).

Integral lifting eyes - for safe and secure on-site handling.

Stabilising feet - stabilising feet prevents the tank from rolling and allows safe and steady transportation and installation.

Unique ‘keying-in’ lip - assists anchoring into granular or concrete surrounds.

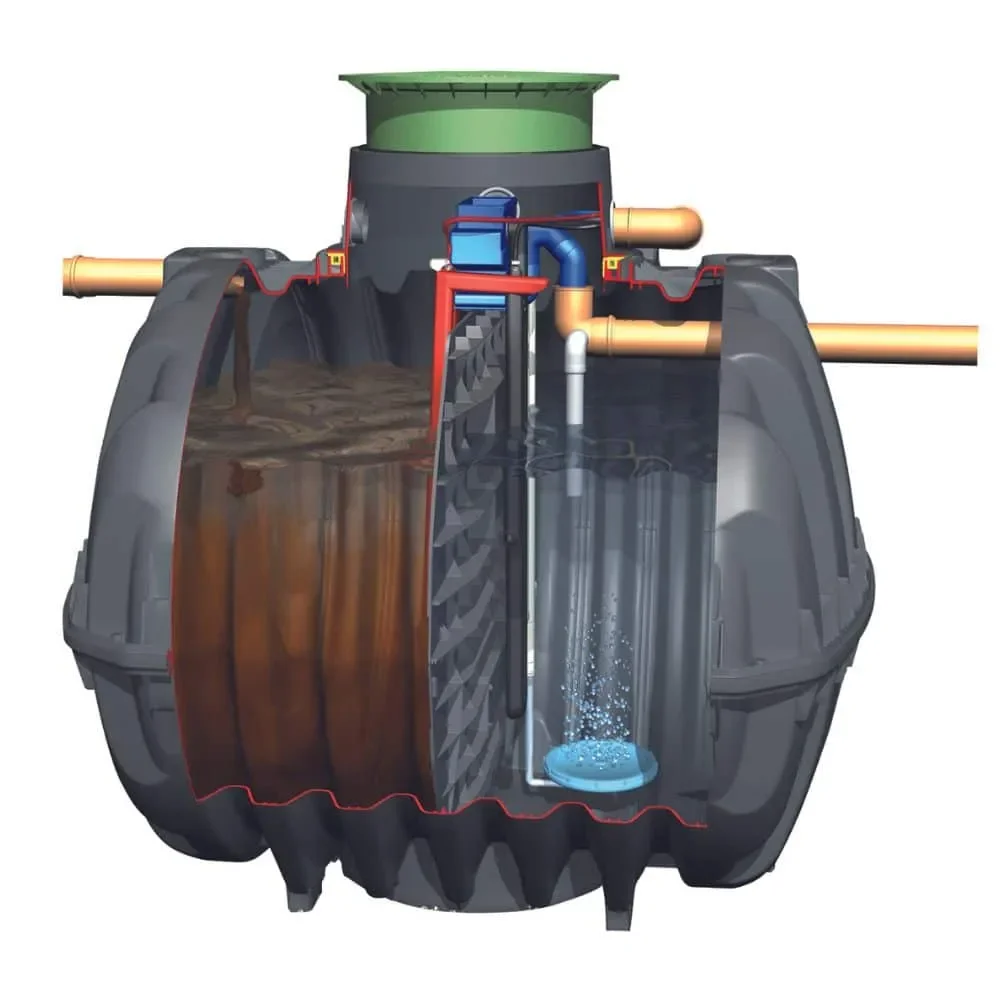

Operating Principle

In addition to anaerobic digestion taking place in the primary settlement chamber [2] the Ensign unit allows the clarified water to pass into a second ‘aeration’ chamber [3] where it is treated to remove the dissolved constituents. Here aerobic bacteria, supported by diffused air and mobile media, ensures full treatment is achieved before the treated effluent and ‘sloughed off’ bacteria flows to a final settlement chamber [10]. The final effluent is then discharged to the drainage field or watercourse via a Polylok filter.

The Ensign:Standard is a robust sewage treatment unit with no internal moving parts, allowing for simple installation, commissioning, and minimal long-term maintenance and cleaning.

Marsh Ensign sewage treatment plants are designed to deliver efficient, reliable, and cost-effective operation.

Units range in size from 4 to 16PE, with larger capacities available up to 50PE. For units above 16PE, please contact our office for pricing. With a wide range of ancillaries, units from this range can meet most site, consent, and budget requirements.

Tested and approved to BSEN12566-3/A1:2009, all Ensign units provide treatment within national consent requirements. Published test results show treated effluent concentrations of 11.5:19.2:8.4 mg/ltr (BOD:suspended solids:ammonia), achieving approximately 97% pollutant removal under test conditions.

Key Features

Inlet & Outlet with ‘Forsheda seal’ - provides flexibility in the joint for easier installation.Optional risers to increase invert depth are available.

Compressor housing – internal or external options available - the compressor can be housed internally or externally with no difference in cost.External recommended to increase compressor life, and supplied as standard on 4PE, shallow and pumped outlet versions.

PVC pressure pipe/diffuser(s) - provides a protective conduit for the air diffuser line. Can be easily removed for maintenance and cleaning.

Bio-media - high specification bio-media (310m3 per m2) and membrane diffusers ensure even circulation to eliminate ‘dead spots’. The bio-media is contained by a stainless steel securing mesh to ensure no migration during handling or potential flooding.

Stainless steel mesh - retains media in aeration chamber during transportation and handling, and in the event of flooding.

32mm sludge return - larger diameter sludge return prevents the possibility of blockages and improves system circulation. Provides higher effluent quality whilst balancing flow over a 24 hour period or periods of intermittent use.

Impermeable lid - heavy duty lid/frame improves strength and durability whilst blending into the surrounding environment. (Regular lid on Ensign:Standard models).

Integral lifting eyes - for safe and secure on-site handling.

Stabilising feet - stabilising feet prevents the tank from rolling and allows safe and steady transportation and installation.

Unique ‘keying-in’ lip - assists anchoring into granular or concrete surrounds.

Operating Principle

In addition to anaerobic digestion taking place in the primary settlement chamber [2] the Ensign unit allows the clarified water to pass into a second ‘aeration’ chamber [3] where it is treated to remove the dissolved constituents. Here aerobic bacteria, supported by diffused air and mobile media, ensures full treatment is achieved before the treated effluent and ‘sloughed off’ bacteria flows to a final settlement chamber [10]. The final effluent is then discharged to the drainage field or watercourse via a Polylok filter.